I. 10kV Series Voltage Regulator

1.1 Project Introduction

The whole 10kV line of a distribution network is 85km long, and the overhead line adopts LGJ-120mm2 steel-cored aluminum strand. Due to the long laying distance of overhead lines, the minimum voltage at the end of 10kV reaches 8.6kV, which seriously affects the normal production and living electricity consumption of downstream residential users.

1.2 Solutions

A 10kV series voltage regulating device is installed at a distance of 10km from the end to compensate the voltage on the 10kV side, so that the grid voltage can be stabilized within the rated voltage range.

1.3 Pictures of On-site Installation

1.4 Application Effects

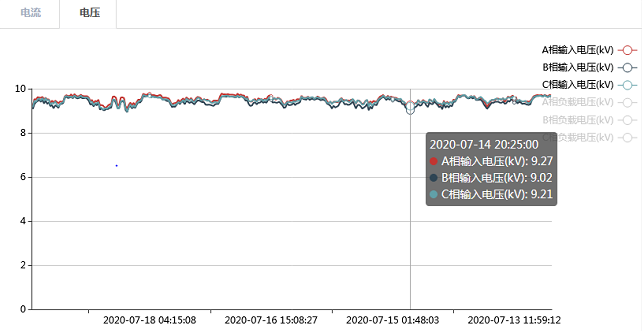

Three-phase voltage before compensation

Three-phase voltage after compensation

Before the 10kV series voltage regulator is put into operation, the voltage at 10km of the terminal line fluctuates around 9kV. Considering that there are load power consumption in the front and rear stages of the device, the compensation output voltage is set to 9.6kV; after the device is put into operation, the voltage is stabilized at about 9.6kV, with good compensation effect, which ensures the stability of the rear-stage power supply.

1.5 Customer Benefits

The 10kV series voltage regulating device is put into operation to make the 10kV voltage meet the national power supply standard, quickly guarantee the normal power consumption of users, reduce complaints and improve user satisfaction. Compared with new substations, it has less investment and shorter cycle, which can save time and manpower and material costs.

II. Distributed power quality comprehensive treatment devic

2.1 Project Introduction

The electricity consumption in residential areas is dominated by single-phase load, and the power consumption time period is relatively concentrated. The problem of three-phase imbalance is particularly serious during peak hours of electricity consumption, and there is a risk of neutral line overload at the same time. In addition, the large number of charging piles put into operation and other non-linear loads used in the residential area also bring reactive and harmonic problems to the distribution network of the community. The existing compensation methods are all centralized compensation in the distribution room. Harmonic interference, reactive power and three-phase imbalance and excessive neutral line current in the lines still exist, which brings influence and safety risks to the normal electricity consumption of residents.

2.2 Treatment Scheme

Distributed power quality control devices are adopted and installed at the cable branch boxes at the ends of distribution lines in residential quarters to locally treat problems such as three-phase imbalance, harmonic wave, reactive power and excessive neutral line current in the lines and ensure normal and safe power consumption by users.

2.3 Pictures of On-site Installation

2.4 Treatment Effect

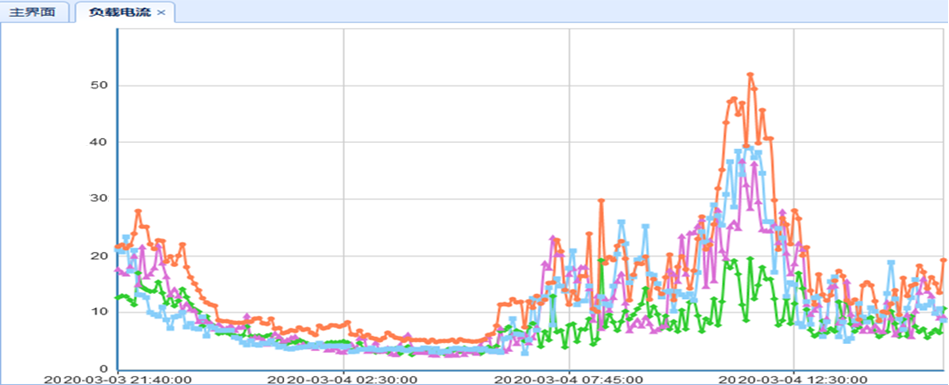

Three-phase current curve at load side before treatment

Three-phase current curve at grid side after treatment

During the peak period of power consumption, the current of phase B is much greater than that of phases A and C. When the maximum current of phase B reaches about 52A, that of phase C is about 36A, that of phase A is about 40A, and that of phase N reaches about 20A at its maximum. After the device is put into operation, the three-phase current tends to be consistent, and the N-phase current is about 3A.

2.5 Customer Benefits

Through the comprehensive management of distributed power quality, solve the power quality problems in residential distribution lines, reduce the loss caused by power quality problems and neutral line current, avoid harmonic interference and neutral line overheating, and improve power supply reliability.

III. Voltage Sag Control Equipment

3.1 Project Introduction

The load in the production workshop of an industrial site mainly includes air compressors and injection molding machines. The power of the air compressor is large, which will cause a short-term drop in the grid voltage when starting up. When the drop depth reaches the voltage protection value of the air compressor and injection molding machine, it will shut down, affecting the normal production of users and causing the loss of production materials.

3.2 Treatment Scheme

The voltage sag treatment equipment is connected in series at the front end of the air compressor to provide voltage support for the air compressor at the moment when it starts, to ensure that the air compressor can start normally and will not be affected by the grid voltage. After the starting voltage of the air compressor is normal, the bypass is automatically switched to reduce system loss.

3.3 Pictures of Site Installation

3.4 Treatment Effect

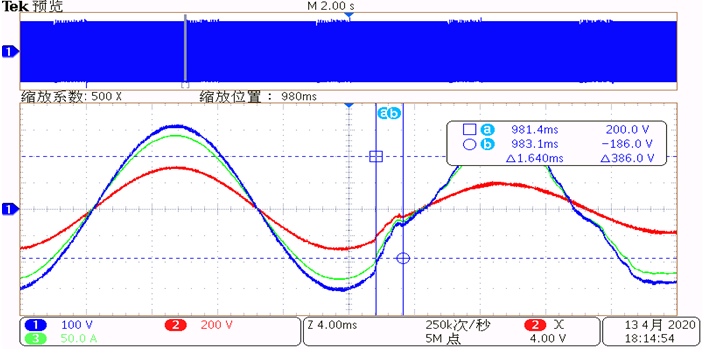

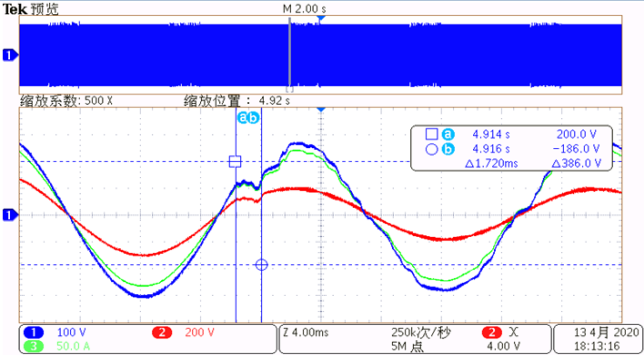

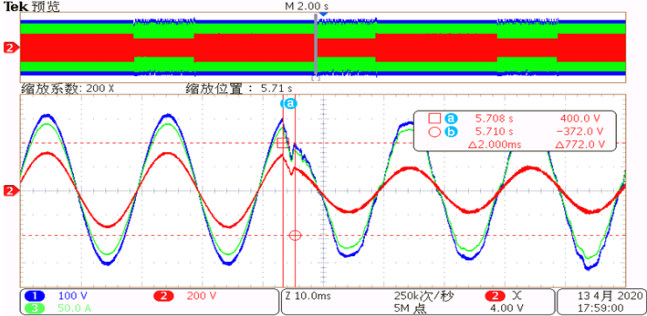

Fig. 1

Fig. 2

Fig. 3

Fig. 1, Fig. 2 and Fig. 3 show the grid voltage sag at 0°, 30° and 60° respectively. It can be seen from the figures that when the grid voltage sag occurs, the voltage sag control equipment can quickly compensate, with a response time of less than 3ms.

3.5 Customer Benefits

The voltage sag control equipment is connected to ensure the normal operation of user's production load and improve production efficiency. In addition, it reduces the waste of production raw materials caused by sudden shutdown of production equipment and saves users' production costs.