China Spallation Neutron Source (CSNS) is a medium-scale high-flux spallation neutron source and one of the "key projects for scientific and technological innovation capacity building" in the Twelfth Five-Year Plan for National Economic and Social Development. Actionpower has undertaken the design and manufacture of the main high-power dynamic magnet power supply. All of them passed the acceptance successfully and have been running stably and reliably so far.

The synchrotron adopts the coating injection method to slowly reduce the intensity of two horizontal bump magnets to change the circulating beam orbit in the injection area, so that the straight beam current enters the synchrotron. Injecting the bump magnet pulse power supply is the excitation source that excites the bump magnet to generate the corresponding magnetic field.

Technical Parameters:

Pulse current: 18000 A;

Peak output voltage: ±3150 V;

Equivalent switching frequency: 800 kHz;

Pulse current rise time: 1000 ms (fixed);

Pulse current flat top: 50 ms;

Falling time of pulse current: 300~550 ms (the falling edge can be flexibly controlled according to the given function of waveform);

Maximum falling rate of pulse current falling edge: 260 A/ms;

Tracking accuracy of pulse current falling edge: < 2%;

Pulse current stability: < ±0.5%;

Operating frequency: 25 Hz;

Continuous working mode: 24-hour continuous operation.

Technical scheme:

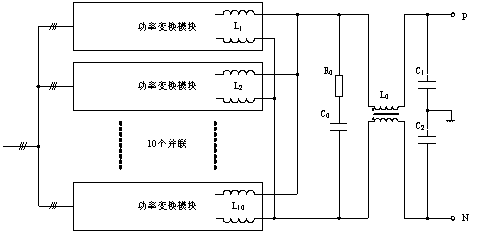

The main circuit scheme of the power supply unit is shown in Fig. 1, and the main circuit scheme of the parallel connection of sub-modules is adopted. Multiple power components are connected in series inside the power conversion module.

Fig. 1 Main Circuit Scheme of Power Supply Unit

The complete machine is realized by connecting 10 power conversion modules in parallel. Each power conversion module includes a rectifier, a step-up chopper and a 4-quadrant chopper. The bus voltage on the DC side is 750V, which is stabilized and controlled by the step-up chopper. The use of a step-up chopper can reduce the fluctuation of input current while outputting a large pulse current. In the four-quadrant chopper, the switch tube is composed of several IGBT half-bridge modules connected in parallel, so that each power conversion module can output at least 1800A pulse current.

The equivalent switching frequency can reach 1 MHz through series multiplexing, parallel multiplexing and in-bridge dualization control, thus improving the tracking control accuracy of output pulse current.

The CSNS/RCS rail coating magnet pulse power supply unit consists of a control cabinet, a distribution cabinet and five power cabinets. The power supply is 7.6m wide, 2.2m high and 1.2m deep.

In December 2008, the official prototype passed the ex-factory acceptance; in December 2009, the official prototype passed the expert review and acceptance on site and fully met the design requirements. In 2013, the two formal power supplies were officially settled in Dongguan Park and the energized commissioning acceptance was completed. In 2018, the whole CSNS project passed the national acceptance.

The site photo of pulse power supply for injecting and coating bump rail magnet is as follows:

The magnet power supply system of the rapid cycling accelerator (RCS) includes 1 set of ring diode iron power supply and 5 sets of ring quadrupole iron power supplies. According to the 25Hz cyclic operation requirements of RCS, the working current of all two-pole and four-pole magnets adopts sinusoidal current with DC bias (IM=IDC+IAC´+sinw0t, where w0=2pf, f0=25Hz, IDC and IAC are the amplitude of DC component and AC component of magnet current respectively). The output current of the power supply is programmed and controlled according to actual needs.

Power supply parameters of two-pole magnet:

Output mode: 25Hz offset sine

Peak current: 2320A

Peak voltage: ±6000V

Current stability: 100ppm

Peak power > 10 MVA,

Average active power about 2.5MW

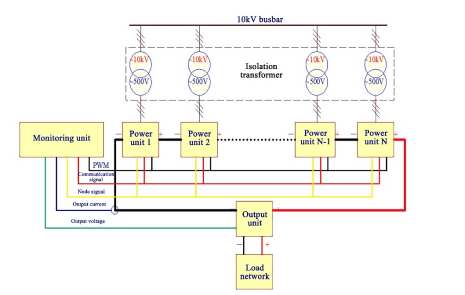

The block diagram of the power supply system for two-pole magnet is as follows:

As shown in the figure above, the system has 10 power units connected in series. Each power unit includes a step-up chopper and a four-quadrant chopper, which are used for voltage stabilization control. The step-up chopper is adopted, and the bus voltage on DC side is 650V. It can also reduce the fluctuation of input current while outputting large pulse current. In the four-quadrant chopper, the switch tube is composed of several large package IGBT half-bridge modules connected in parallel, so that each power unit can output at least 2320A peak current.

Through series multiplexing and H-bridge chopping circuit dualization, the equivalent switching frequency of the power supply system can reach 40kHz to ensure multiple harmonic injection.

The CSNS/RCS dipole magnet has the largest power and volume. The complete machine consists of a control cabinet, an output cabinet and 10 power cabinets. The power supply has a total width of 13.8m, height of 2.2m and depth of 1m.

In 2010, the quadrupole magnet power supply prototype passed the prototype acceptance; in 2015, 5 sets of formal power supplies were officially settled in Dongguan Park. In 2016, they were successively commissioned and accepted. In 2018, the whole CSNS project passed the national acceptance.

Photos of the main magnet power supply site are as follows:

Technical Parameters:

Output mode: dynamic

Output peak current: 3000A

Output peak voltage: 30V

Current stability: ±0.2%

Bandwidth: >10kHz

Photos of power supply site: